These days, it’s tough for a warehouse to keep up with customer demands and expectations. The Cargo Spectre team talks every day with logistics companies that are interested in adding warehouse automation to their tool chests in order to deliver products faster, maximize warehouse space, and reduce costs, among other benefits. Most aren’t sure where to begin, and are wary of the potential costs involved.

But what if we told you there were a few, simple warehouse hacks for automated efficiency that can transform your business without big, upfront costs? We love using technology to solve large-scale challenges for warehouse owners. If you’re curious to learn what simple changes we recommend to solve inefficiencies and eliminate errors, read on!

Our 5 Simple Warehouse Hacks for Automated Efficiency

1. Big Data and Analytics

“Big data” means large volumes of hard-to-manage data taken from sources like transaction records, freight reclassifications, or measuring equipment. The more data you can collect, the clearer the picture of your warehouse operations becomes. It can provide so many insights that help your business identify upcoming trends and spot potential opportunities.

That’s where predictive analytics come in. As the name implies, predictive analytics forecast upcoming events and situations by studying past data. You can even begin to forecast upcoming opportunities and prepare for coming challenges ahead of time!

RELATED: HOW CARGO SPECTRE DIMENSIONERS BOOST WAREHOUSE THROUGHPUT

2. Remote Warehouse Management

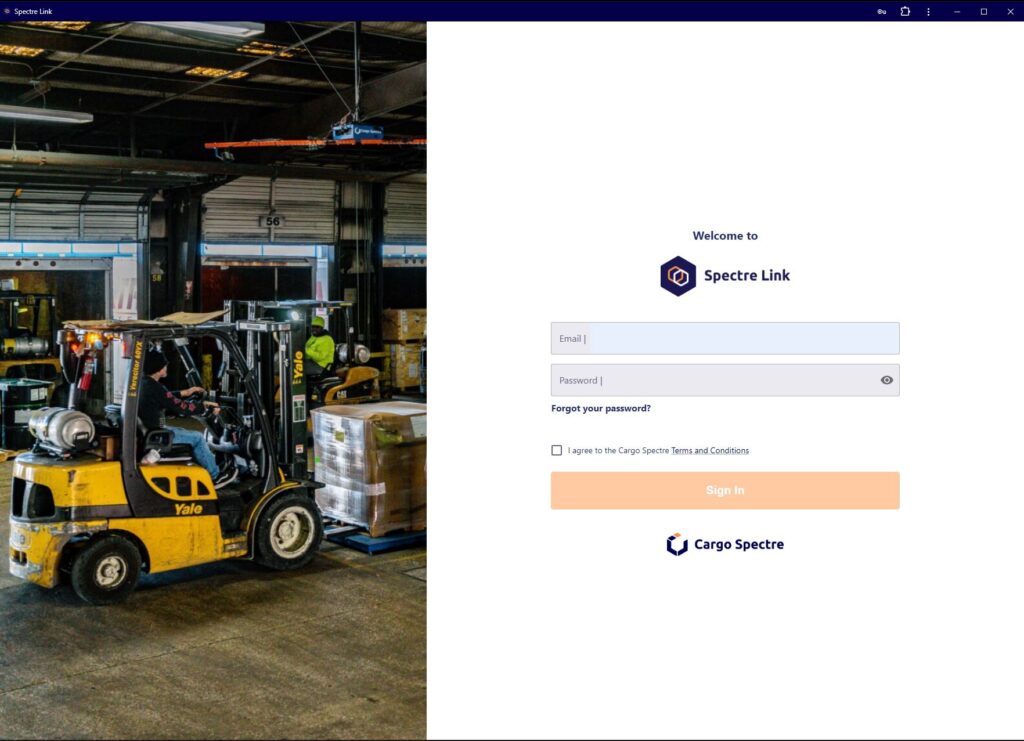

Thanks to technological innovation, warehouse management doesn’t necessarily require boots on the ground or eyes on the team anymore. You don’t even have to be on site! Remote warehouse management tools give you a real-time look into your daily warehousing operations and allow you make business decisions on the fly, no matter where you are.

This is especially useful if your company runs multiple warehouses or distribution centers, meaning you don’t have to bounce around several locations just to ensure everything (and everyone) works. You won’t believe the time and miles it saves!

3. Cloud-Based Warehouse Management Systems (WMS)

In the olden days, WMS providers installed warehouse management systems on giant servers that took up space in your warehouse. Even worse, you had to arrange a vendor visit to get upgrades or fix problems.

Cloud-based WMS eliminates these challenges, making things much easier for modern warehouses and distribution centers. Instead of physical server installations, you simply access the WMS through the Internet. Your WMS vendor can also install updates and fix issues remotely without arranging a visit.

4. Wireless Scanning

Wireless scanning has come a long way from the checkout line at the supermarket. Today, hand-held scanners can collect item information like SKU and manufacturer code, which can be used in other operations within the warehouse. Scans can even trigger actions, like label printing or billing, all while helping to eliminate costly human errors.

5. Top-notch Support

“Tech support” might not seem like a revolutionary hack, but this may be the MOST critical of all. The difference between quality, on-demand support and slow, costly vendor support can affect your bottom line just as much as any technology on this list. Reliable support keeps the machine of automation running smoothly. If you can’t count on your support team to minimize downtime and solve challenges quickly and affordably, you need to rethink your support solution.

From installation to troubleshooting to optimization, you’re going to need a dedicated support team behind you to ensure that your warehouse automation systems are tuned up and running flawlessly. And because you never know when you’re going to need help, they need to be available to you 24/7, worldwide. Anything less means downtime, and that means profits lost. That’s why 24/7 worldwide support is a MUST for modern warehouse automation.

RELATED: SOLVE WAREHOUSE STAFFING SHORTAGES WITH CARGO SPECTRE

Where Cargo Spectre Comes In

At Cargo Spectre, we believe in these warehouse hacks so much that they are built into the DNA of every product and service we offer. We know automated operational efficiency is the key to the logistics industry’s future, because we see and hear the challenges that warehouses are facing every day. Every Cargo Spectre system is designed and installed to be a valuable building block in a fast-paced, error-free warehouse of the future!

That may sound a little grandiose, but we take pride in offering better, modern solutions to age-old problems. If you aren’t sure how our logistics automation systems can help your business improve its bottom line, give us a call for a free consultation. We’ll take your specific needs into account and make custom recommendations that will put you on the road to practical automation!