Return on investment is a huge factor for most carriers when choosing a dimensioning system, and with good reason. We all go into business to make money, not spend it. But when deciding if dimensioning is worth the investment, many carriers tend to focus only on the potential revenues that can be recovered by correcting misclassified freight. While that’s certainly a significant source of revenue, it isn’t the only one.

Accurate Costing Data

Collecting accurate costing information on customers is a huge benefit when discussing and re-negotiating rates, and Cargo Spectre provides the data that allows you to make your case conclusively. In an industry where weight and freight class drive revenues billed, underperforming customers can slip through the cracks with improperly classed or priced freight—especially when you have thousands of customers who ship wide varieties of freight daily.

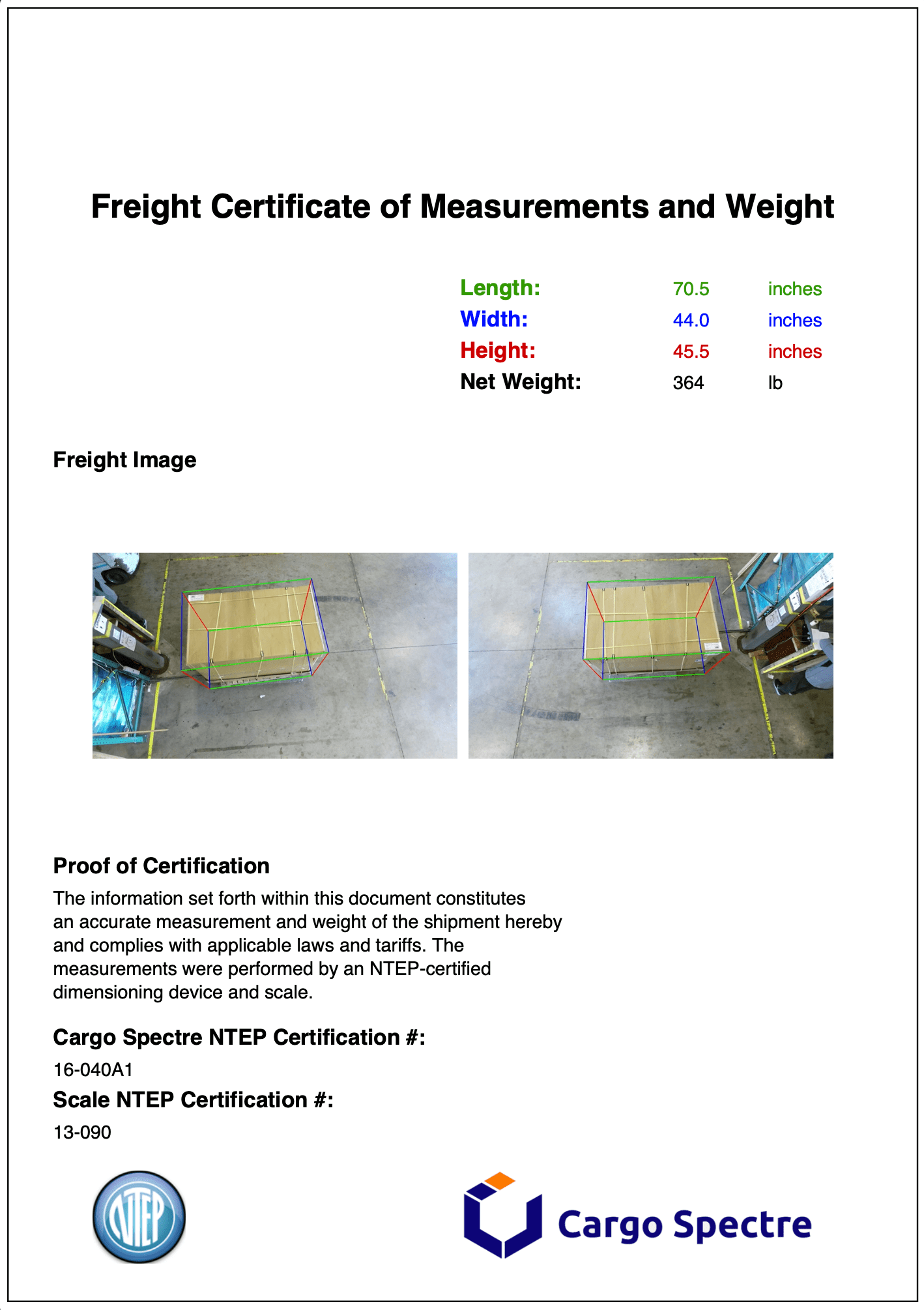

Previously, the only way to recover lost revenue and identify these underperforming customers and target them for new contract negotiations was to identify their freight through random weights and measurement inspections. That was a tedious, labor-intensive process that Cargo Spectre made obsolete. Today, the answer is fast, simple NTEP-certified dimensioning data that makes your margins crystal clear in seconds.

Recovering Revenues

In Cargo Spectre’s internal research into carriers that were dimensioning at least 40 percent of all available freight, we found that they were able to increase their revenue by more than $3 for each pallet they dimensioned. That $3, multiplied by thousands of pallets dimensioned each day, led to hundreds of thousands of dollars in extra revenue in just a week or less. What’s interesting is that even though actual rate adjustments only occur on an average of five percent of shipments scanned, the revenues recovered exceeded the cost of the Pallet Spectre in a very short period of time.

“We found that they were able to increase their revenue by more than $3 for each pallet they dimensioned. That $3, multiplied by thousands of pallets dimensioned each day, led to hundreds of thousands of dollars in extra revenue in just a week or less.”

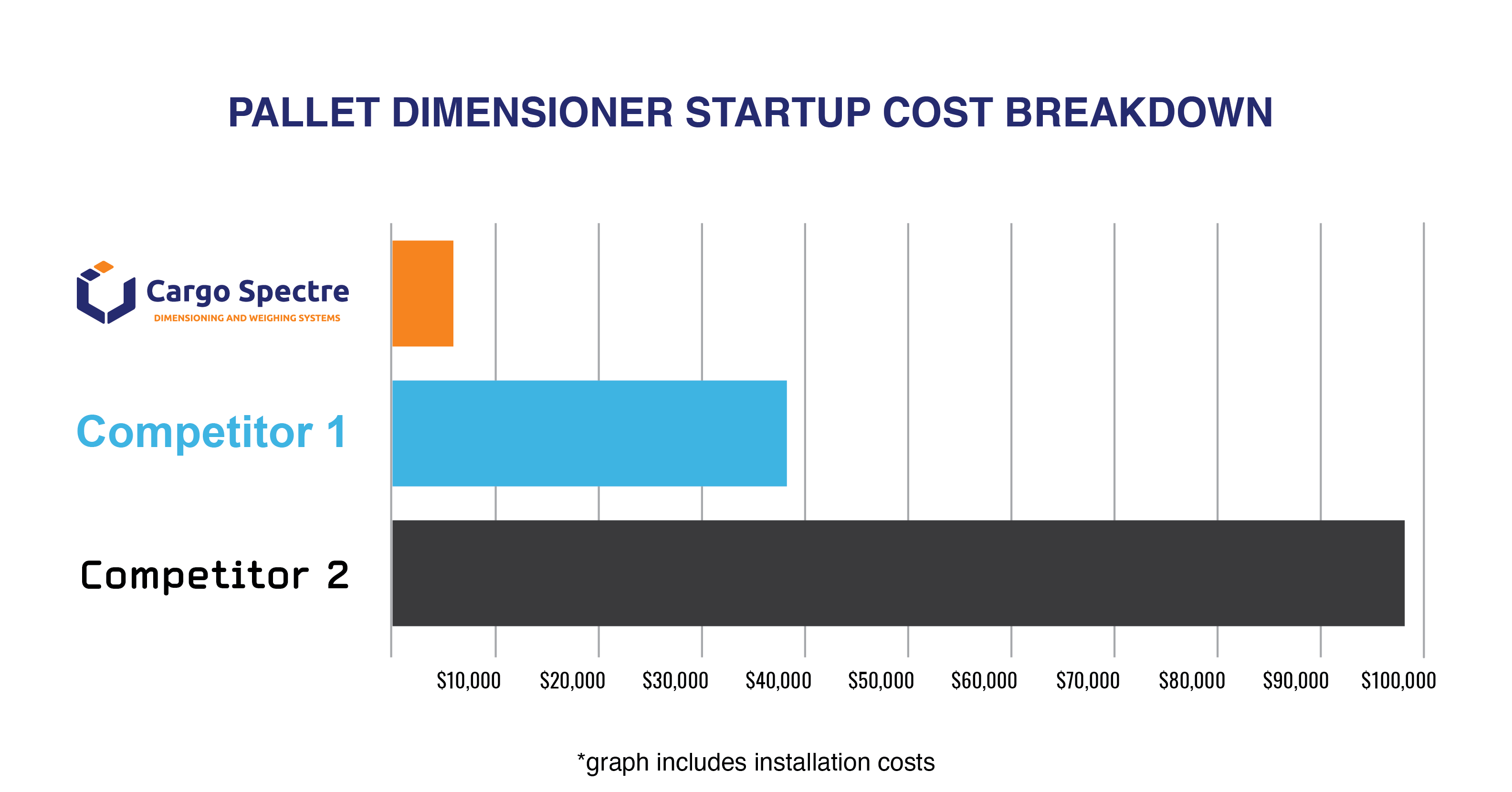

Our competitors require their customers to invest heavily in equipment up front. Cargo Spectre charges less up front. We require only a one-time upfront cost of $6,000 for the equipment, installation, and training. That includes $3,500 for equipment and installation, $1,500 for training, and $1,000 for travel. After that, Cargo Spectre utilizes a monthly billing model, so you won’t need to make a big investment up front to get up and running with our freight dimensioner systems. Simply pay one, all-inclusive monthly fee for as long as you need our system.

Thanks to our pay-as-you-go pricing model, a carrier can expect to recover the total cost of a Pallet Spectre dimensioner in a month or even less.

Let’s Get Started

Our machine-learning software innovations have made us a global leader in the industry, and we serve clients all over the world for less. Contact us today for more information on how you can add the power of A.I. freight scanning to your operation for only a month.